A Comprehensive Overview to Comprehending Litho Printing Methods

The world of litho printing, a technique stemming from the late 18th century, is an interesting blend of history, scientific research, art and technology. This thorough guide will certainly unravel the intricacies of this printing method, from the structure of litho inks to the difficulties encountered in modern applications. As we venture right into the complexities of lithography, the relevance of automation and sustainability in guaranteeing its future significance comes to be increasingly clear. Stick with us as we trip right into the fascinating world of litho printing.

The Historical Development of Litho Printing

The historic trajectory of litho printing, a pivotal development in the world of interaction, is a captivating tale of human ingenuity. Birthed in the late 18th century by Alois Senefelder, this technique was originally a cost-effective technique of publishing theatrical jobs. Lithography, originated from the Greek words for 'rock' and 'to create', made use of a smooth rock surface area to transfer pictures onto paper. The procedure evolved with the arrival of the rotating press, which greatly enhanced efficiency (litho printing). In the 20th century, the technology of offset lithography changed the sector, enabling automation of high-quality prints. Each stage of litho printing's advancement showcases humanity's unrelenting quest of effectiveness and quality in visual interaction.

Deciphering the Science Behind Litho Printing Inks

Moving on in the exploration of litho printing techniques, the emphasis now shifts to the scientific research behind litho printing inks. The make-up of these inks, their drying out procedure, and color mixing strategies form the foundation of this intricate art type. Comprehending these elements is critical to grasping the craft and achieving the preferred print results.

Structure of Litho Inks

In lithographic printing, the essential role of litho inks can not be overemphasized. The structure of litho inks varies relying on its function, but usually, they contain two primary components - automobiles and pigments. Pigments, the color-providing components, are carefully ground fragments suspended in the vehicle, a liquid that lugs the pigment onto the printing surface. The automobile is a complex blend of solvents, oils, and materials, which influence the ink's drying out time, adhesion, and gloss. Furthermore, various ingredients exist to enhance particular homes like flow, drying, and resistance to environmental impacts. Each part plays a crucial component in the last print's high quality, making the precise formula of litho inks an elaborate scientific research.

Ink Drying Process

From the structure of litho inks, focus turns to the fascinating procedure of ink drying out. 2 main techniques are utilized in litho printing: oxidative drying out and absorption. Absorption, on the other hand, includes the ink permeating into the paper fibers, which is a faster procedure but can lead to much less vibrant colors.

Shade Mixing Techniques

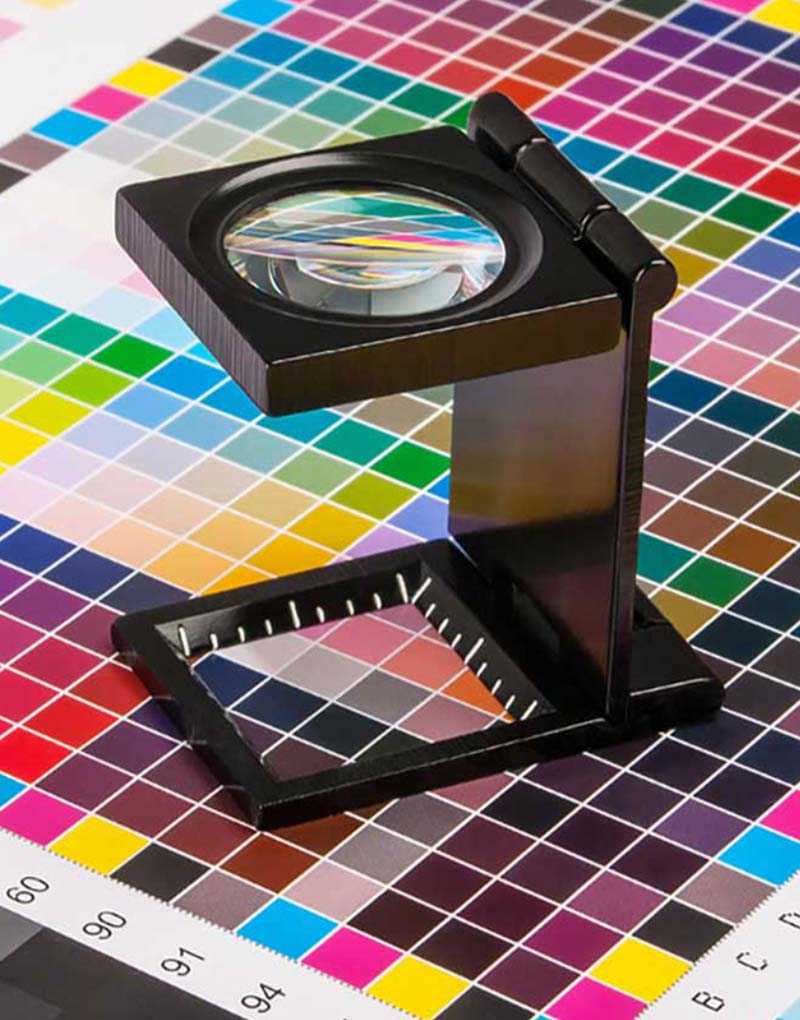

While the drying out procedure plays a crucial function in litho printing, the scientific research of shade mixing techniques holds equal importance. This is a complicated procedure that entails the cautious mixing of primaries: cyan, magenta, and yellow, in differing proportions to achieve a large array of hues. The addition of black ink, called 'crucial', aids in controling the strength and depth of the shades. The scientific research behind litho printing inks likewise takes into consideration the transparency of the ink, which impacts just how colors overlay and mix. To achieve a reliable color mix, print experts have to also comprehend the complexities of ink behavior, color theory, and the physical buildings of the substrate on which the ink is applied.

The Art and Style Components in Litho Printing

Litho printing takes a breath life right into art and design with its unique components. The procedure involves creating an image on a lithographic limestone plate or steel plate with a smooth surface. The image is then published onto a medium, generally paper, by transferring the ink from the plate. What collections litho publishing apart is its capacity to replicate elaborate layouts with high fidelity, making the output virtually the same to the original art work. This is accomplished with using various line methods such as stippling, hatching, and cross-hatching, which permit a series of tonal results. Litho printing suits a selection of colors, enabling musicians to develop vivid and vibrant prints. This mix of precision and convenience makes litho printing a recommended choice for many artists and developers.

Modern Applications of Litho Printing Techniques

Litho printing methods have located comprehensive use in the modern business industry. Its impact look at these guys and importance remain to grow with the introduction of new innovations and innovations in the field. This area will discover these modern applications and the transformative role they play in the printing industry.

Commercial Litho Printing Utilizes

Litho printing remains an important part of the business field. High-volume printing tasks, such as the manufacturing of books, newspapers, and product packaging, count on litho printing for its capability to deliver exceptional image high quality and price performance. Litho printing also supplies a broad shade range, remarkable to that of electronic printing.

Innovations in Litho Printing

Pressing the limits of standard methods, modern-day improvements have read what he said actually fueled a host of technologies in litho printing. These developments have not just boosted the quality and efficiency of litho prints but also expanded its application range. One famous growth is electronic litho printing, which integrates the virtues of electronic innovation with litho's high-quality outcome. This crossbreed design uses faster setup times, reduced waste, and makes it possible for on-demand printing. One more significant advancement is the introduction of environmentally pleasant inks. These inks, made from vegetable or soy-based remedies, have actually considerably decreased the industry's environmental impact. litho printing. Furthermore, the growth of advanced plate modern technology has streamlined the printing procedure, leading to sharper photos and improved shade fidelity. These advancements emphasize the long-lasting importance of litho printing in the modern-day globe.

Exploring the Process of Litho Printing: Action by Action

Challenges and Solutions in Contemporary Litho Printing

Regardless of the accuracy and custom that litho printing proudly maintains, it is not without its set of contemporary obstacles. Digital litho printing permits for economical brief runs and easy customization, addressing the problem of variable information. Therefore, while there are challenges, the litho printing industry is proactively adapting to meet them head-on, ensuring its relevance in the future.

Verdict

Finally, litho printing, with its abundant background and scientific intricacies, holds a significant location in the print industry. As the overview discloses, it's a synthesis of art and technology, with modern-day advancements guaranteeing its importance. Nevertheless, the sector faces obstacles that need cutting-edge options, with a concentrate on automation and sustainability. The future of litho printing depends upon its ability to adjust to these altering needs, attesting its enduring worth in an evolving market.

Comments on “Uncover the Longevity and Detail of litho printing”